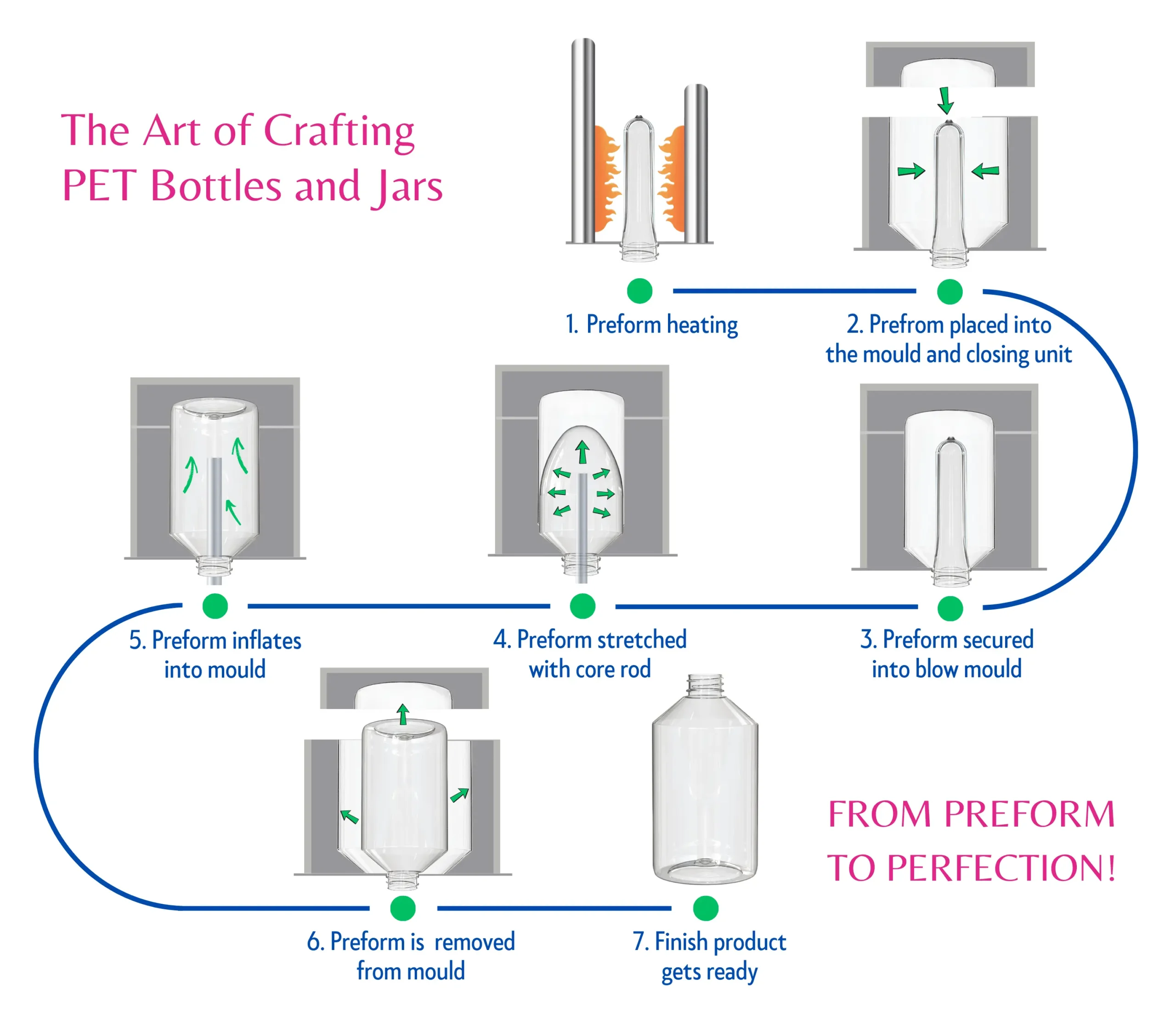

Manufacturing Process

PET is a thermoplastic polymer that helps to produce plastic bottles and jars. The PET must undergo polymerization to form long molecular chains to manufacture plastic containers. This complicated process is conducted remarkably at Crystal Plast Industries with every batch of PET. We eliminate the chemical impurities and their concentrations to ensure product safety.

Once the process gets finalized, the manufacturing begins:

Product Testing

Several tests are done after manufacturing to guarantee that the bottles and jars are safe for use. We inspect factors such as

Transparency

Ensures the clarity of PET bottles and jars for an appealing appearance.

Weight

Verifies consistent material usage for durability and efficiency.

Gloss

Checks the surface finish for a polished, high-quality look.

Resistance to Creep

Ensures the bottle retains its shape under stress or pressure.

Drop Testing

Tests durability by dropping the bottle to check for breakage.

Capping

Verifies the cap fits securely for reliable closure.

Leakage Test

Ensures the container is leak-proof to prevent spills.

Several tests are done after manufacturing to guarantee that the bottles and jars are safe for use. We inspect factors such as

Transparency

Weight

Gloss

Resistance to creep

Drop testing

Capping

Leakage test

Several tests are done after manufacturing to guarantee that the bottles and jars are safe for use. We inspect factors such as

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Several tests are done after manufacturing to guarantee that the bottles and jars are safe for use. We inspect factors such as

Transparency

Weight

Gloss

Resistance to creep

Drop testing

Capping

Leakage test

State-of-the-Art Machinery

At every step, our innovative and robust machines give the highest level of productivity. We use the latest machinery that provides great efficiency and helps in mass production.

Our reliable machines that ensure premium quality product manufacturing consistently are:

Injection Moulding

At Crystal Plast Industries, we use the injection moulding method to produce moulded products such as PET Preforms and various Caps and Closures for mass production.

Stretch Blow Moulding

We have adopted the two-step automatic stretch blow moulding machine that produces multiple sizes and shapes of Pet Jars and Bottles from 50 ml to 15000 ml.

Extrusion Blow Moulding

The Plastic extrusion moulding machines allow us to reduce wastage and help manufacture custom PET Jars and Bottles, making us a reliable supplier in the market.

Our state-of-the-art Flashforge Guider 2S 3D printer builds several professional high-quality designs. It’s a user-friendly industrial 3D printer that prints the product structure precisely with ultimate accuracy.